Unsere IT Recruitment Dienstleistungen für Unternehmen

FullService IT Recruitment Paket

IT-Spezialisten sind schwer zu finden?

Wir übernehmen den gesamten Rekrutierungsprozess.

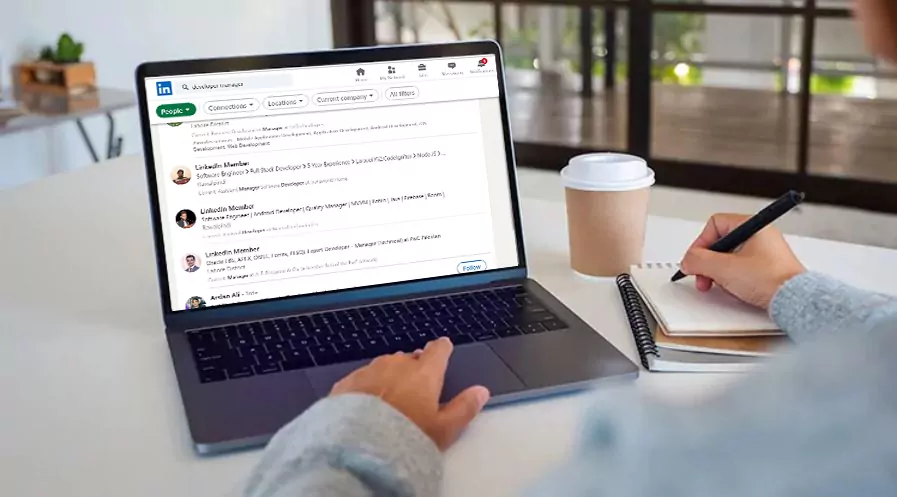

IT Active Sourcing Paket

Erhalten Sie Lebensläufe von Bewerbern für Ihre IT-Stellen zu einem günstigen Festpreis.

Internationale IT Experten

Haben Sie schon einmal darüber nachgedacht, IT-Spezialisten einzusetzen, anstatt sie einzustellen?

Es ist an der Zeit, dies zu tun.

Wir sind spezialisiert auf die Vermittlung von

IT-Fachkräften

Wir nutzen unsere 25-jährige Erfahrung in der IT-Branche, um Arbeitgebern dabei zu unterstützen, die besten

IT-Talente zu finden. Wählen Sie aus unseren IT-Recruitment-Dienstleistungen je nach Ihren Prioritäten und Ihrem Budget. Wir vermitteln auch internationale IT-Experten für Ihre schwer zu besetzenden IT-Stellen.

0

Jahre Erfahrung

0+

Länder aus denen unsere

Mitarbeiter arbeiten

IT-Personaldienstleister, der schnelle Unterstützung leistet

Selbstrekrutieren funktioniert möglicherweise nicht für alle, aber das bedeutet nicht, dass Sie aufgeben sollten.

Ihre Zeit ist kostbar. Deshalb unterstützen wir Sie bei Ihrer Mitarbeitersuche und dem kompletten Einstellungsprozess.